I would like to report that I was able to remove the motor and transmission this weekend as I had intended, BUT it rained. A lot! I was able to brave the rain long enough (and after $40+ in new sockets larger than one inch) and snag the transfer case. I am sad to say that when I drained the transmission that water was the first fluid that came out of the case. I now know that a complete rebuild of the transmission and transfer case await me.

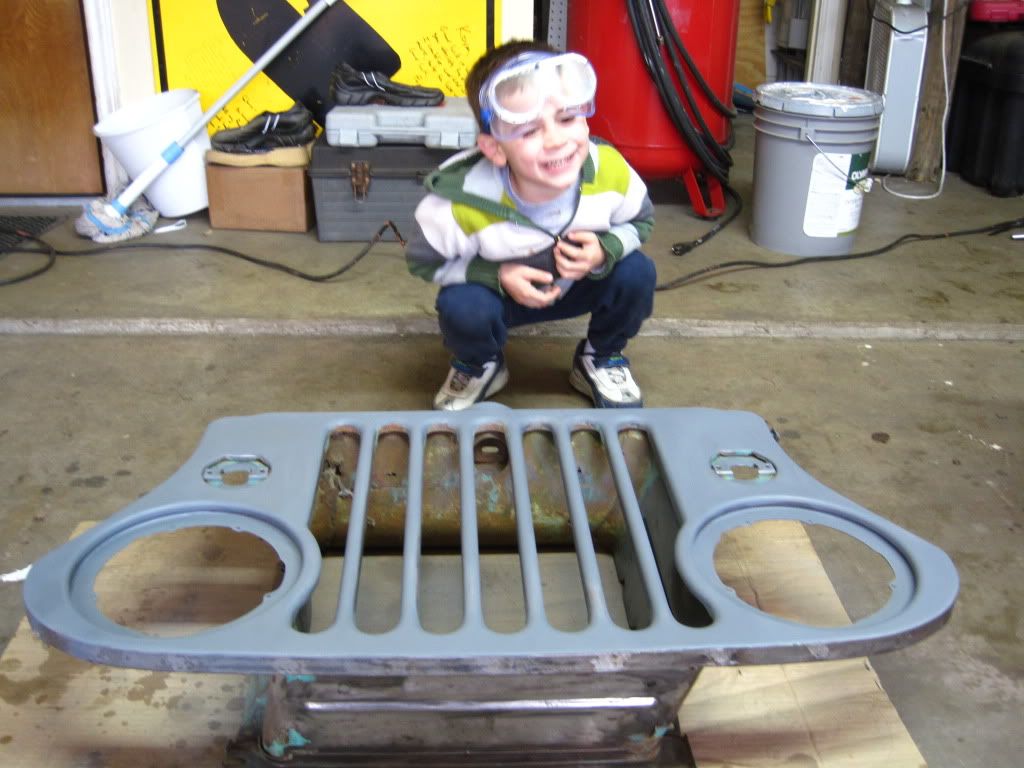

The weekend was not a total loss however. I was able to bring in the grill (as seen in the previous post) and then the cowling. Mike was home and I had been neglecting him all day so I thought that this would be a good opportunity to have him come out and work on the Jeep. We first swept the floor and got rid of a lot of junk. Next we washed our hands, put on clean gloves, and then washed and dried the grill. He was really getting into helping daddy out.

When the grill had a chance to dry I began shaking up a can of primer. Mike wanted to know if this was going to be the blue paint that I had promised him. I then had to explain that we have to paint the Jeep one color before we can paint it another. I am sure that this seems very odd to a five year old, but he bought into it.

Now finished shaking the can I pointed it at the grill and what came out was, well really nothing. I stood up and turned the can away from Mike (who I had made wear glasses and gloves) and promptly sprayed a shot of primer into my left eye. In a great amount of pain I asked Mike to open the door so that I could rinse my eye out. A splash of water and the world was right again. This Jeep hates my eyes!

Painting finished I sent Mike inside to play with his toys. "Dad, can I play Wii?" "No, play with your toys." Right, Right! I set to work cutting out rusty areas on the cowling and patching them back up. I believe that I covered a bit of this in my last post, but that post was after working on the Jeep for ten straight hours. In short the process is pretty simple. You find a hole, inspect the area to see just how far the rust has eaten away at the metal, cut a larger hole that removes rust and thin metal, next you take a new sheet of metal and stick it under the hole. Once you have traced your shape the cut off wheel comes out and you cut your patch to size. Then comes the fun part, you get to tack and weld in your patch into place. If I am honest, I am rubbish at welding and make quite a hash of things (sorry I have been listening to a lot of British speak). A short conversation with my father about my skills brought to light that I was trying to weld at a 45% angle. His explanation was that with my wire welder I was pushing the shielding gas away from the area that I was trying to weld. I began welding at closer to 90% and you know what happened? I began getting much better welds and burning through the body a lot less. This also means that I do not have to be as aggressive with the grinder when I finish things up. Thanks Dad! This Jeep may be a gift from my mother's side of the family, but it is what I learned from my father over the years (Yes, that includes putting tools back where you found them when you have finished with them)that will allow me to complete this project.

I have a lot of work to do to get things straight before painting, but it feels good to have accomplished something. I will be taking nine hours this semester. School may really put a dent in my progress, but the plan is to have this sucker rolling by the summer. If that is to happen I have to find some magical elves to drop by and lend a hand.

Enjoy the new photos.

No comments:

Post a Comment