Good afternoon,

This will not be a long post. I feel as if I have been run over by something large after the time that I put into the Jeep project today. I started working at 9:00am and knocked off at 11:00pm. I wish that I could say that something wonderful happened today, but that was not the case.

So, 9/16th you ask... That this the size of the #$%#$^)(@#$ wrench that I needed all day long. A wrench, mind you, that kept getting up and walking off to some other place that I know that I could not have left it. I have more than one 9/16th wrenches, but you just don't leave your tools about in the hopes that you will discover them later.

A bad PLF (Parachute Landing Fall for all of you legs.)? Mike wanted to ride his skateboard today. It had been raining all day, and with a break in the weather I felt that getting out would be good for him. As he stood on the board I tried to tell him how to steer, but to no avail. I told him to watch me, and sure enough he said that he then understood. Great, I stop, turn around, push off back toward Mike, and wham. Blacktop and my head meet! For those of you that have never jumped you are supposed to land: feet, knees, rear end, back, shoulders. This is what is known as a PLF. Ask anyone that has ever jumped how many of these landings they have had. The answer will most likely be a big fat ZERO. This is because God loves to giggle as paratroopers burn in. On any given jump you are likely to land; feet, ass, head. Today when I fell off Mike's board I landed; ass, head.

Things blurred, but I was able to stay with it. Mike must have known it was bad because I told him to get his board and he did without asking questions. Once inside I told him that I was hurt, that it was not his fault, and this is why we do not skateboard.

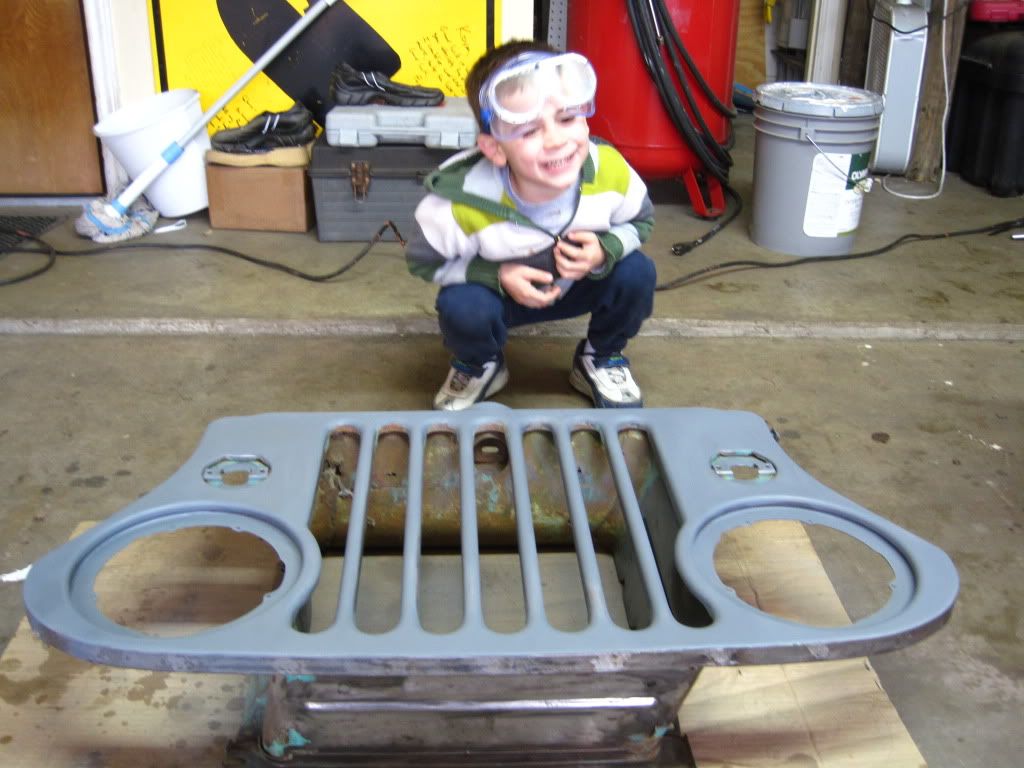

On to Eviction. Rusiko lost her ability to park in the garage today. It was raining, and in order to get anything accomplished I had to drag body parts into the garage. She was a good sport about it.

Enjoy the photos!

Here you can see the door hinges once used in place off a real hinge.

Cutting out rotten patches.

Cutting off windshield hinges.

Holding a skin graft in place. I am using metal from other parts of the old Jeep to weld into the holes.

Time to pass out!